Gas appliances safety precautions

Gas engineers should ensure that any appliance they install, or flue to which they connect an appliance, is safe for use. Requirements in regulations should be met as applicable, and reference made to appropriate standards. Appliances should be installed in accordance with manufacturers’ instructions, including any manufacturers’ instructions on flues to which the appliances can be safely connected. This regulation imposes an important and wide-ranging duty on the engineer to ensure that nothing about an appliance itself, the manner in which it is installed, any associated fitting or flue, or other factor (eg ventilation) will cause danger when the appliance is taken into use. This ‘all-embracing’ duty interfaces with other parts of GSIUR dealing with more specific safety aspects of appliance installation, and requirements under regulation for examination/testing after any work on an appliance, including installation.

In addition to the duty under regulations, regulation 30 places restrictions/prohibitions on the installation of certain appliances. The installation of an open-flued appliance in the same room (this includes a through lounge) as a solid-fuel open fire, or an appliance with a fan-assisted flue, is not recommended because it may have an adverse effect on the performance of an existing flue. No person shall connect a flue domestic gas appliance to the gas supply system except by a permanently fixed rigid pipe. Flexible connections should not be used as this could allow consumers to move the appliance away from the flue. No person shall install a used gas appliance without verifying that it is in a safe condition for further use. The physical condition of any used appliance should be checked before installation. This is necessary as suitable inspection might not be possible after an appliance has been installed. In addition to second-hand appliances, this regulation also applies when an appliance is moved from one location to another, even within the same room.

No person shall install a gas appliance which does not comply with any enactment imposing a prohibition or restriction on the supply of such an appliance on grounds of safety. No person carrying out the installation of a gas appliance shall leave it connected to the gas supply unless –

- (a) the appliance can be used safely; or

- b) the appliance is sealed off from the gas supply with an appropriate fitting.

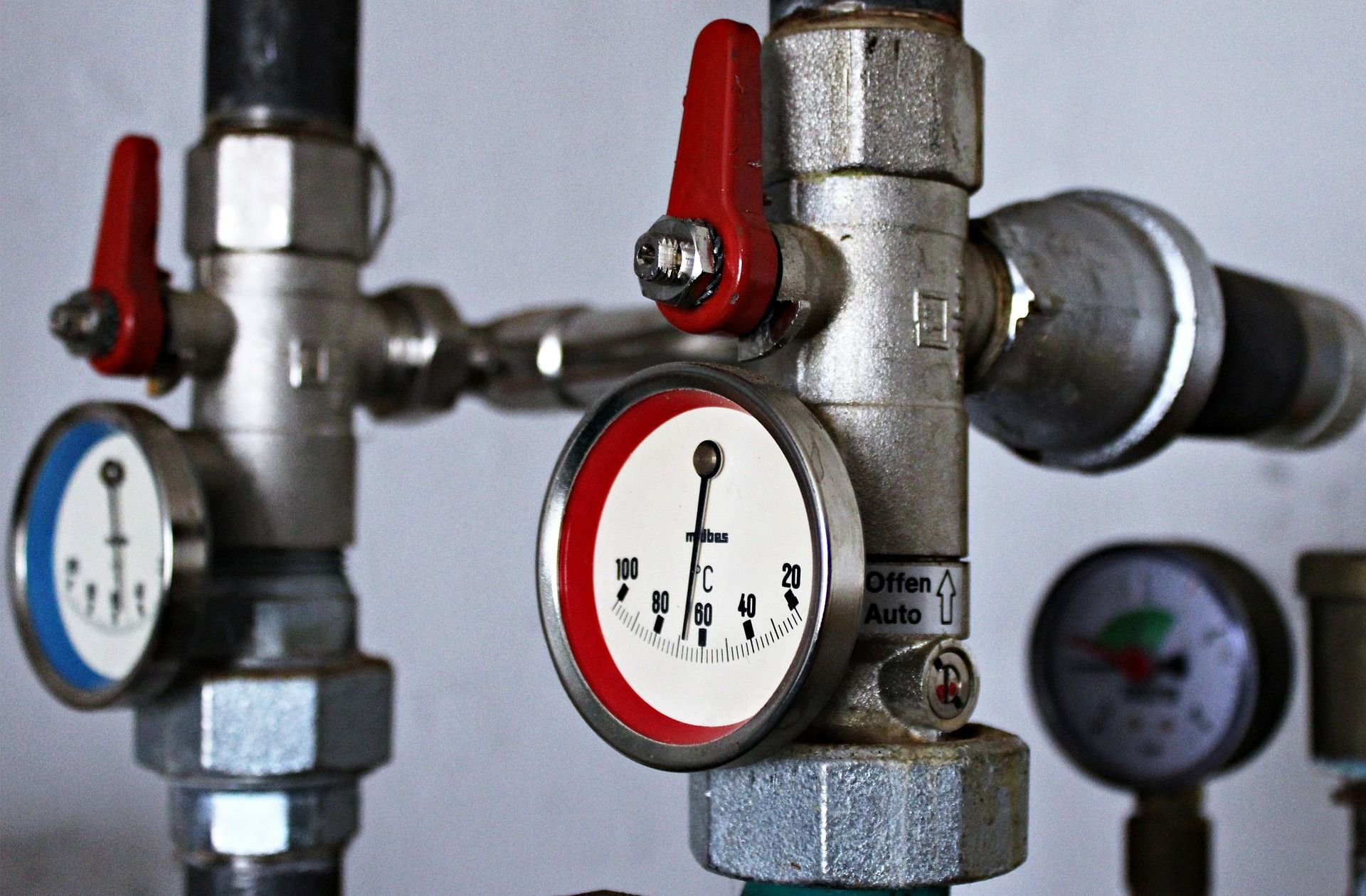

No person shall install a gas appliance without there being at the inlet to it means of shutting off the supply of gas to the appliance unless the provision of such means is not reasonably practicable. The means of shutting off the gas supply to an appliance may comprise either a conventional isolation valve or other effective means, eg a self-sealing plug-in connector (commonly used on cooker installations) or a screw-down restrictor elbow (such as used on gas fire installations). A shut-off device at the inlet to a gas appliance is regarded as part of ‘installation pipework’ for the purpose of these Regulations. The shut-off device required under this regulation assists tightness testing of installation pipework and allows an appliance to be isolated/disconnected in case of an emergency, eg if the appliance develops a gas leak or otherwise becomes dangerous. Although the regulation recognises that provision of a shut-off device at the inlet of an appliance might occasionally be difficult, there will be few, if any, situations where this is not reasonably practicable.

No person shall carry out any work in relation to a gas appliance which bears an indication that it conforms to a type approved by any person as complying with safety standards in such a manner that the appliance ceases to comply with those standards. No person carrying out work in relation to a gas appliance which bears an indication that it so conforms shall remove or deface the indication. Where a person performs work on a gas appliance he shall immediately thereafter examine the effectiveness of any flue; the supply of combustion air; its operating pressure or heat input or, where necessary, both; its operation so as to ensure its safe functioning.

conformity (eg ‘CE’) marking on the appliance. Any repair to a gas appliance, for instance involving use of refurbished or reconditioned parts, should be done in a way which ensures safety standards are maintained. Engineers should refer to manufacturers’ specifications/instructions and appropriate standards. Regulations requires the operating (ie gas) pressure and/or heat input of the appliance to be checked. The engineer should carry out the most appropriate test(s) for the appliance. This information is usually shown in manufacturers’ installation instructions, or on the appliance data badge. In certain cases, eg when appliance burners are modified or replaced, such as for conversion from LPG to natural gas, it may be necessary to check both operating pressure and heat input. Regulation applies only to work on gas appliances, it does not cover work on certain other gas fittings, eg meters and installation pipework (that might be carried out remote from an appliance). See definitions of 'gas appliance’ and ‘gas fittings. Appropriate checks and tests are still required to ensure safety after any work on such fittings.

Under regulations, the tests/examinations in regulations are not required after certain work on appliances. The exception applies, for instance, to the direct disconnection of an appliance, ie where the appliance is itself detached from the gas supply, such as at the appliance connector or a nearby pipework connection. (Indirect disconnection, eg resulting from removal of another fitting upstream, such as a meter, is separately excluded as this is not regarded as work on a gas appliance. Regulations also does not apply to purging of air or gas from an appliance, eg in the process of resuming a gas supply after interruption, but this is conditional on the purging operation itself having no adverse affect on the safety of any gas fitting. (This would not preclude the possibility of an appliance defect present before, and completely unrelated to, the purging activity still remaining after purging has been completed; such defects would need to be detected and addressed separately.

To establish whether the safety of any gas fitting might be affected by purging, a competent person should make an assessment before the operation is carried out. In any case of doubt or where safety is likely to be affected, the tests/ examinations in regulations should be carried out after purging has been completed, and remedial action taken to make appliances/fittings safe, as necessary. It should be stressed that the exceptions in regulation 26(10) apply only to those activities specifically mentioned and if other work is carried out in association with these activities, eg any adjustment of appliances after purging, the requirements in regulations again need to be met Engineers need to take account of manufacturers’ instructions and any safety warnings given by them, especially any recall-type information about safety problems encountered with appliances some time after the particular model was first introduced onto the market If any safety defect is found as a result of the tests/examinations under regulations, the responsible person, and (if appropriate) the landlord for the premises, should be notified as soon as possible. If neither is available, the gas supplier or transporter should be notified as appropriate.